Pneumatic cardboard waste stripping machine paperboard carton stripper waste shaving machine

|

Item Number |

HS-890 |

|

Type |

Pneumatic stripper |

|

Color |

Silver |

|

Revolution |

4500 turns /min |

|

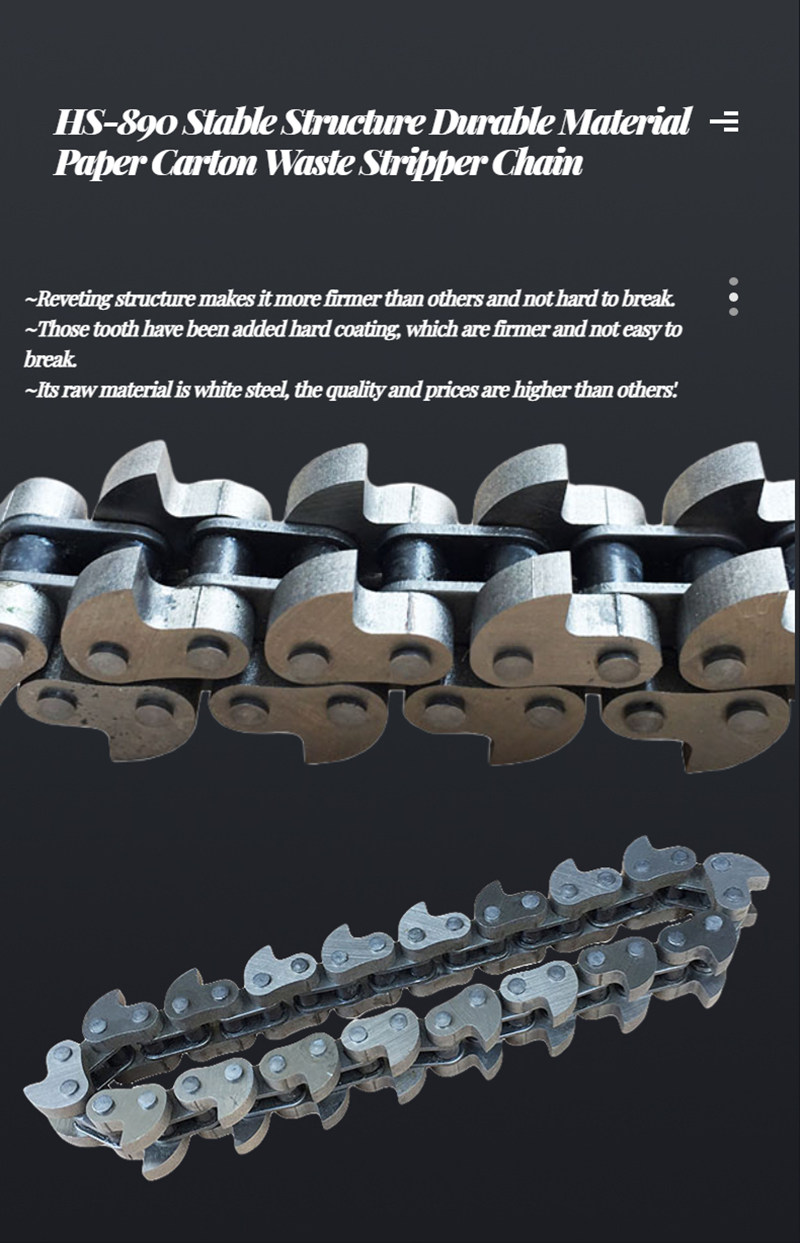

Chain |

#2 with 18 cogs (large size) |

|

Air consumption |

0.4㎡/min |

|

Working pressure |

6~8 KG |

|

Net weight |

5.5 KG |

|

Minimum cutting size |

5MM |

|

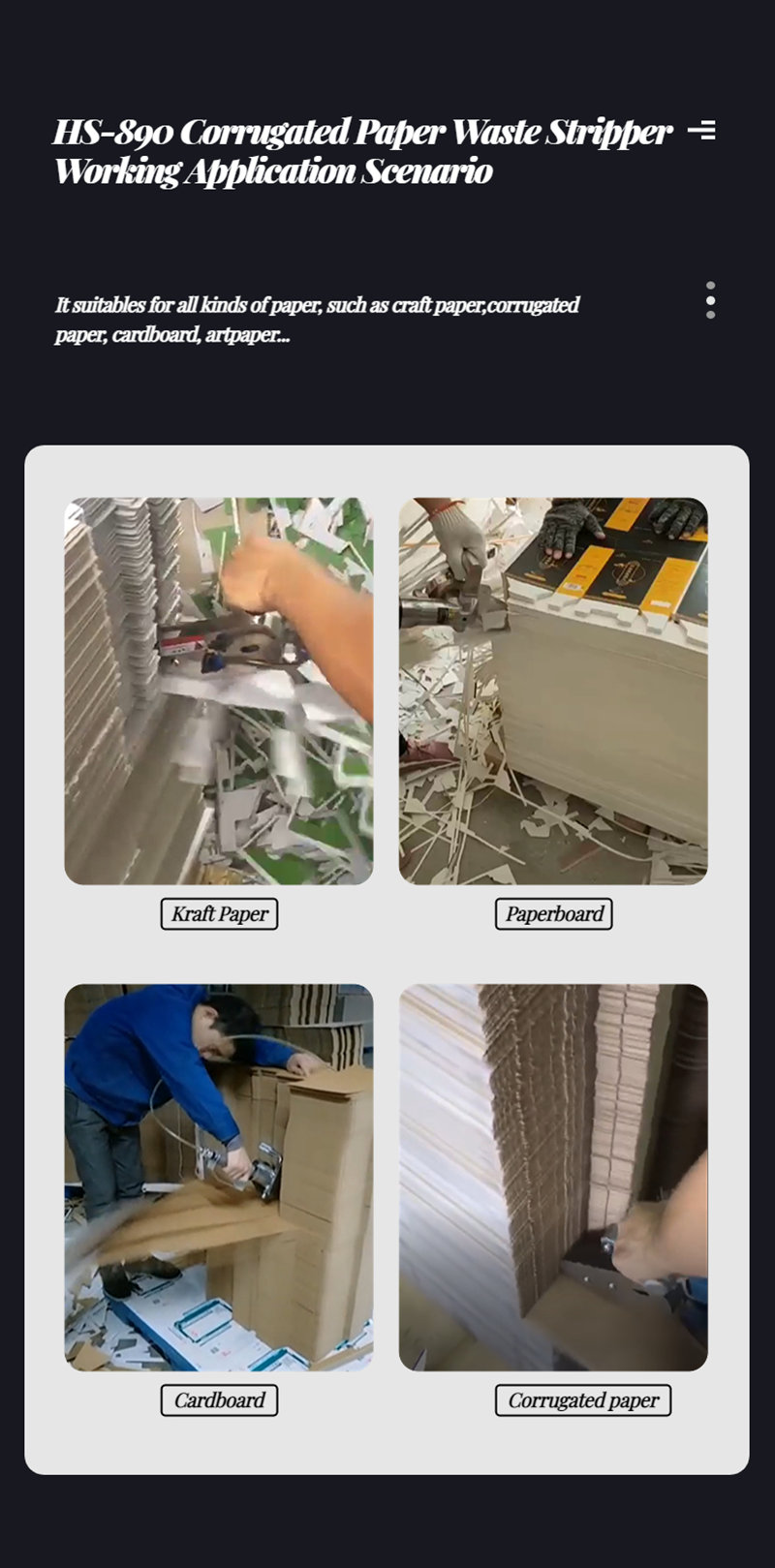

Suitable paper |

all kinds of paper. Efficiency will be higher for greyboard paper, corrugating medium paper and so on. |

|

Gross Weight |

6.0KG |

|

Package Dimensions |

490*170*240mm |

Operating Instructions

1, Connecting the pneumatic carton waste stripper machine to air compressor. The air compressor operating pressure should be more than 0.6 KPA. For electric carton stripper machine, please connect it to the 220V power.

2, Clutch handle with left hand grip and Grip the motor handle with your right hand. Turn on the machine and work by both hands.

3, Machine's chain will rotate by high speed after turning on the machine. Place the machine on the edge of the waste paper and gently press the hands down to force

4, The waste paper edge from the chain should be cleaned up to the designated point in time.

Warm reminder: Beware of chain wounds

PRODUCT DISCRIPTION

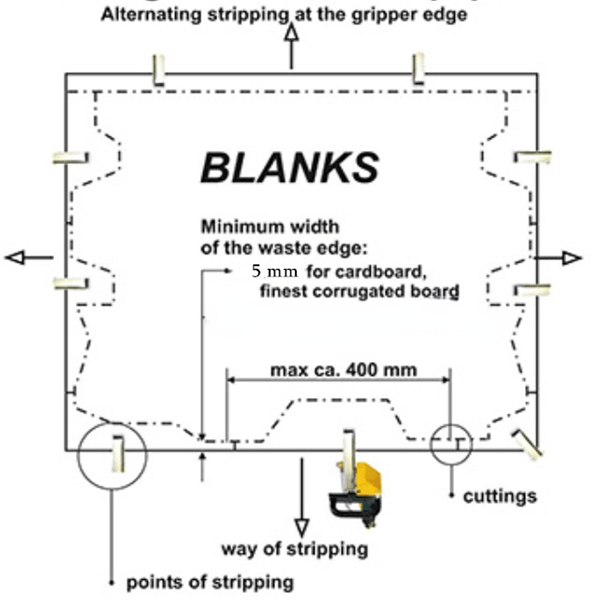

The compressed air driven HS-890 carton-stripper has a very narrow and filigree chain (the minimum waste edge width is 5mm). This stripper should be used only for very small die-cut waste which is deeper in the stack, but can be used for normal waste too.

Our pneumatic types HS-890 is very robust and very low-maintenance. For the US and UK market, all pneumatic types are also available with a two-handed safety system.

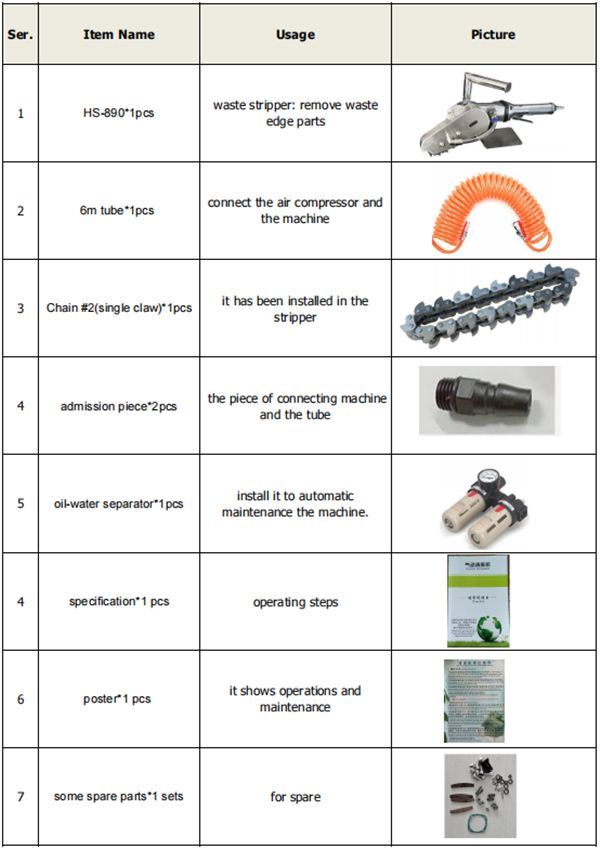

For the HS-890 carton stripper, we will free to offer you the lubrication unit. (Filter with water separator, reduction valve, pressure gauge, air line lubricator, mounting bracket and screws). It is absolutely necessary to use a lubrication unit to protect the air driven motor.

HS-890 STRIPPING TOOL IS THE MOST EFFICIENT SOLUTION TO REMOVE DIECUT-WASTE.

Lightning-fast stripping of the outer die-cut waste from carton, craft paper and corrugated board stacks with our HS-890 carton-stripper.

Finish the time‐consuming and stressful waste‐stripping by hand. Our HS-890 carton‐strippers allows lightning fast removal of die‐cut waste from folding carton, e‐flute, cardboard, microwave‐ , corrugated board, gray broad paper and craft paper. When breaking out the die‐cut waste with our HS-890 carton‐stripper, the sheets remain exactly stacked as they left the die‐cutter. Designed to meet the requirements of our customers, our HS-890 carton‐stripper have proven their worth in carton board and board processing worldwide for 15 years.

Requirements for using our technology

Prerequisite for using our technology is that the outside trim must be cut into trim sections. Except from this is the clutch edge. This will be stripped out reciprocally, on the left and right side. Please see the below principle picture for waste segments.

Subdivide the waste edge in a way that the chain can operate at the widest part of the waste edge. Furthermore, the smaller the number of nicks (to heed at new forms), the faster the stripping operation will go. HS-890 carton‐stripper removes the trim section by section at high speed. A section of the stack of 250 sheets high can be removed in one second for instance. This performance results in a substantial lowering of manual stripping cost.

Maintenance Method

1,The machine should be maintained after using 2-3 days. If the using time is more than 15 hrs per day, you should maintain the machine once a day.

2, The maintain operations for pneumatic stripper machine: Apply the specialized air-tool oil to the air inlet of machine. And apply the regular engine oil to the chain of machine. Then turn on the machine to let it rotate about one minute. You can also install the oil-water separator to automatic maintenance to discharge of water in the air compressor every day.

3, The maintain operations for electric stripper machine: Apply the regular engine oil to the chain of machine and Lift the machine with both hands. Then turn on machine to let it rotate by one minute. Please replace the carbon brush when the motor power drops.

For details, please read the instructions of machine.

Summary of the function

Scope of application: This clear the waste machines are used cardboard ,corrugated paper and fine corrugated paper in the printing of the profession .The function is clear out the waste side .Apply to the paper of 150g—500g.

Characteristic of the function :

1. Function:This clear the waste machines clear out the waste side are through the motor of pneumatic ,it is spurred on the chain and tooth.

2. Characteristic :

(1) This machine is very quick of the equipment, than the work efficiency of power has gone up 5—10 times at least.

(2) The machines are structural concise, the weight is light and portable, it is simple and easy to use.

(3) The motive force is adopt the pneumatic, reliable life grows and safety, the qualified of fire prevention.

(4) The chain are made of steel, the hardness is very high, and durable.

Parameter of the technology :

1. Barometric pressure :0.63Mpa

2. The compressor of air needed over 4 KW.

Order List

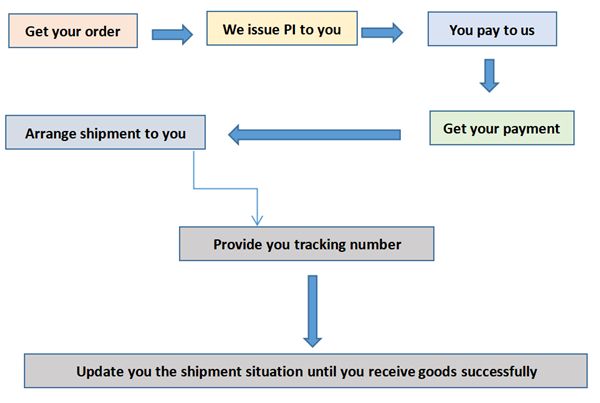

Lots of available carton-waste-strippers in stock are waiting for you, we will send out goods at once after getting your payment.

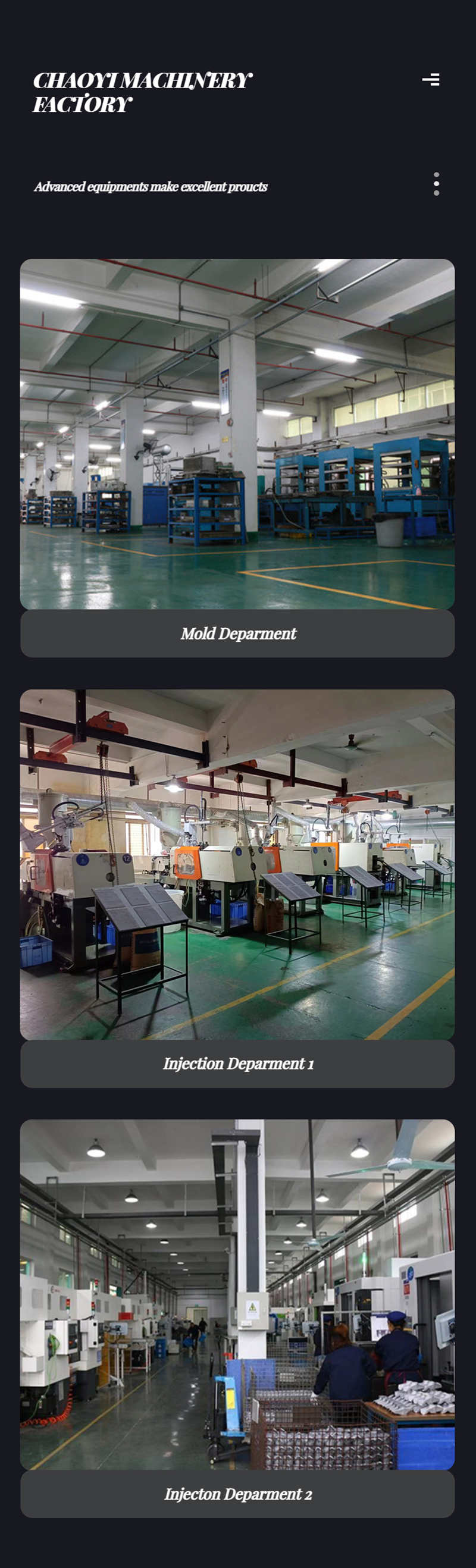

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD