Semiautomatic Handheld Cardboard Waste Edge Stripper

PRODUCT SPECIFICATION

|

Item Number |

CH-18 |

|

Type |

Pneumatic stripper |

|

Color |

Orange |

|

Revolution |

4500 turns /min |

|

Chain |

#3 with 18 cogs (medium size) |

|

Air consumption |

0.4㎡/min |

|

Working pressure |

6~8 KG |

|

Net weight |

3.5 KG |

|

Minimum cutting size |

5MM |

|

Suitable paper |

all kinds of paper. Efficiency will be higher for corrugating medium paper/paperboard |

|

Gross Weight |

6.0KG |

|

Package Dimensions |

490*170*240mm |

The CH-18 waste stripping machine is a user-friendly, handheld device designed to remove waste from die-cut sheets, suitable for various types of paper, including solid carton board, with a minimum waste depth of 5mm.

The latest iteration of the CH-18 is equipped with a heavy-duty motor and powerful pneumatic drive, ensuring the chain’s durability for at least six months when used correctly.

Key Benefits:

Up to 85% reduction in stripping time

Time savings on back and side trim removal during die cutter setup

Two-handed operation for enhanced safety

Hardened components for extended lifespan

Ultra-hard chain and enclosed pneumatic system for improved safety

Reduced risk of repetitive strain injury (RSI)

Narrowest minimum gutter depth on the market at 5.0mm, resulting in undamaged cartons and improved productivity

Product Features:

Utilizes a renowned pneumatic motor for high performance and security

Lightweight and portable design for exceptional convenience

Enables quick and efficient waste removal, surpassing traditional manual stripping methods

Prevents damage to the bonding area during stripping, unlike hammer-based waste removal

Features a high-strength alloy steel chain for enhanced hardness, wear resistance, and prolonged service life

Common Issues:

1, Tool does not work

maybe cause 1: Chain does not rotate, too tight or gear stuck: Remove the cover, adjust the slider, and check for misalignment between the chain and gear.

maybe cause 2: Paper jam in gear during operation: Cut off the air supply and manually agitate the chain to remove the jammed paper shreds.

2, Tool rotation powerless

maybe cause 1: Insufficient air pressure: Check and increase the air pressure as needed.

solution 1: Verify that the slide switch is in the correct position.

solution 2: Adjust the chain tension to the appropriate level.

3, If the chain is excessively worn, it needs to be replaced.

WHY CHOOSE US

Here are some main points.

|

Chain |

Riveting Chain

|

More firmer and not hard to break. |

|

Metal Cover |

Stainless Steel Cover

|

It is easy to extremely hot and easy to dissipate heat, which can protect stripper by itself |

|

Metal Handle |

Stainless Steel Handle |

Elegant and is high quality. |

|

Firm structure |

Three points fixation |

More firmer and more stable |

|

Inside components |

Hard Coating |

Longer lifetime and high quality |

|

Motor |

Famous brand |

High accuracy, stability and excellent quality |

PRODUCT SHOW

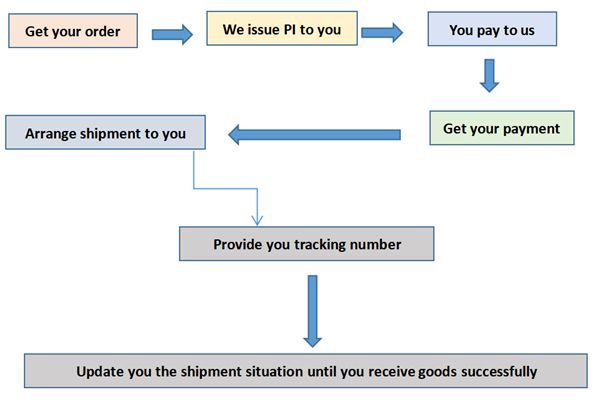

ORDER STEPS

How to maintain the waste stripping machine

The machine should undergo maintenance every 2-3 days (once every 2-3 days). If the machine is used for more than 12 hours per day, it should be maintained daily.

Maintenance operations: There are two methods of maintenance, manual maintenance, and automatic maintenance using an oil-water separator.

Manual maintenance:

Apply regular engine oil or pneumatic tool oil to the machine’s chain.

Apply specialized air-tool oil to the machine’s air inlet.

Turn on the machine and let it rotate for about one minute.

Automatic maintenance by oil-water separator:

Install the oil-water separator at a location 1 or 2 meters away from the air compressor.

It will automatically maintain the machine while it is in operation.

For details about the oil-water separator, please refer to the information below.

SHENZHEN CHAOYI MACHINE CO.,LTD

SHENZHEN CHAOYI MACHINE CO.,LTD